Blog

PHE Gasket Types of Attachments/Installation

There are different types of attachments for the gaskets to be fixed on the plates, depending on the requirements and the plate design.

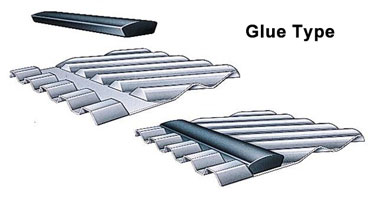

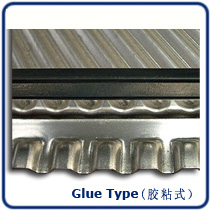

Glue Type: The glue is used to fix the gasket into the groove on the heat transfer plate. Usually it only used for some PHE which doesn’t need to be cleaned time by time, because attaching and de-attaching the gaskets takes much more time than other types.

Clip Type: The heat exchanger gasket is positioned on the heat transfer plate and held in place by clips, at specific areas, around the edge of the plate.

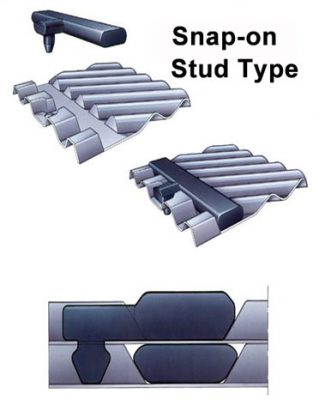

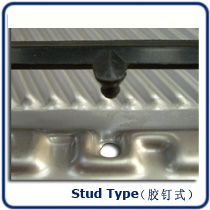

Stud/Snap-On Type: This is similar to clip type but instead of attaching to the edge of the heat transfer plate, part of the gasket (stud) is pushed through the plate, using a specific tool. Someone calls it Stud type while others call it Snap-On type.

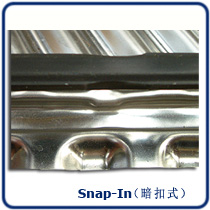

Snap-In Type: The gasket is positioned on the heat transfer plate. At specific points the gasket groove has narrow sections, which the gasket is pushed (snapped) in to. There are several different variations which are with special designs. One of the variations is with extra parts in the side to be put into the groove side, which is specially designed.

The following images shows the example of different types.

When you are going to buy PHE gaskets, it’s suggested that you take a photo of the old gasket so that we can know which type it is of.